Thermal transfer is a type of printing that occurs on a ribbon. Ink from the ribbon is transferred onto the material in which it’s being applied. Direct thermal printing, on the other hand, occurs directly onto a substrate instead of a ribbon, which is the main difference between these two printing methods.

Thermal transfer technology is often used by companies with high barcode labeling and alternative labeling needs. Images produced by this type of printer are high-resolution and durable in many different environments.

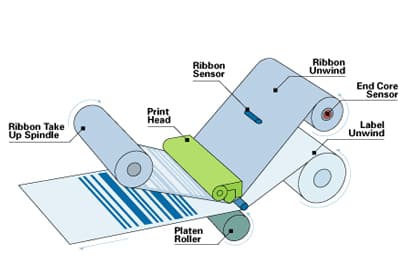

How Does a Thermal Transfer Printer Work?

The thermal transfer printing process occurs when the elements within the thermal printhead produce heat that melts thermal transfer ribbon (TTR) ink. The melting process causes the ink to transfer onto the substrate to produce the desired image. The ink in the ribbon is usually made from wax, resin, or a wax-resin compound. The ribbon types should be chosen based on the project because they each produce a different print quality.

These units work quickly. They contain sensors that notify the internal computer when the TTR roll is out to help protect the printhead.

The main benefit of this printing method is the high-quality, durable images that result. However, the ribbons are one-time use only, which is where the direct thermal method gains an advantage.

Here’s a bit more detail on how each of the thermal transfer printer components work, and the role they play in the imaging process.

Components

THERMAL PRINTHEAD

The Thermal Printhead is the most important mechanism. It consists of a fixed number of heating elements corresponding to its printing resolution. When fired, these heating elements transfer heat through the TTR and onto the label substrate. This combined with pressure completes the printing process by transferring the melted ink to the label substrate.

RIBBON UNWIND

The Ribbon Unwind is located in front of the Label Unwind and serves the primary function of holding the TTR roll in place while the thermal printer is running. TTRs are wrapped around Fiberboard Cores that fit perfectly into the Ribbon Unwind. The Ribbon and Label Unwinds are both pulled under the Thermal Printhead by the Platen Roller.

LABEL UNWIND

The Label Unwind holds the roll of labels in place. The labels are placed on the Label Unwind and fed through the Platen Roller along with the TTR. As the thermal transfer printing process continues, the Platen Roller pushes the labels out of the unit.

PLATEN ROLLER

The Platen Roller is usually a stationary roller centered directly under the thermal printhead and serves as a multi-functional component. A small motor spins the Platen Roller and guides the TTR and label through the unit and under the printhead for printing. The Platen Roller is also used to help feed the TTR and label into the unit.

RIBBON TAKE-UP SPINDLE

After the thermal ribbons have been pulled through the Platen Roller and Thermal Printhead, they must be manually attached to the Ribbon Take-Up Spindle. This piece rotates in the opposite direction of the Ribbon Unwind to collect the TTR after it has passed through the thermal printing process, allowing for easy disposal of used ribbon.

RIBBON SENSOR

This component is extremely helpful as it senses if a TTR is in place. This sensor also detects the end of a TTR roll and notifies the internal computer when it has reached the Trailer film. Not all thermal transfer printers use a ribbon sensor—some use an End Core Sensor (see description below). Both sensors have similar functions—to detect the end of a TTR roll.

END CORE SENSOR

The End Core Sensor is located inside the Ribbon Unwind and its primary function is to detect lack of motion. This process works closely with the TTR’s End Film, which is loosely attached to the Fiberboard Core. When the TTR reaches the end of its roll, the constant rotating motion will detach the End Film from the Fiberboard Core and the Ribbon Unwind will cease its rotations. The End Core Sensor will detect this lack of motion and notify the internal computer to stop printing.

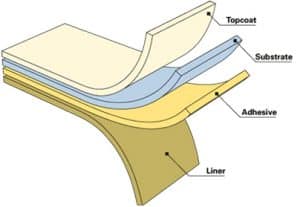

SUBSTRATE COMPONENTS

The substrate is the label material that the thermal transfer printer will produce the image on. Here are the main components:

- LINER – The liner is almost always a paper material with a silicon coating. Its primary functions are to promote easy handling of the label before and during printing, and to protect the adhesive layer. The liner is removed at the end of the process when the label is ready to adhere to its intended object.

- ADHESIVE – This layer forms a bond between the substrate material and the object to which it will adhere. There are many types of adhesive, each designed to meet specific application requirements. Consider the following when choosing:

- if the label needs to be permanently affixed to a surface or easily removed,

- whether the surface to which it will be applied is rough or smooth,

- and if the label will be used in any extreme environments (e.g. high temperature or high humidity).

- SUBSTRATE – Substrate layers are made of paper or one of many different types of synthetic material, depending on the desired durability of the application. The substrate is the actual material that carries the printed image.

- TOPCOAT – The Topcoat layer is almost always present for thermal transfer receptive labels. This layer encourages adhesion of the various inks to the substrate layer.

Here at Peak Technologies, our expert team can help you determine if thermal transfer printing is the right method for your business, and they can help you get the products you need to get your printing system up and running efficiently.